PandaBuy's Standardized QC Process with Spreadsheet Technology

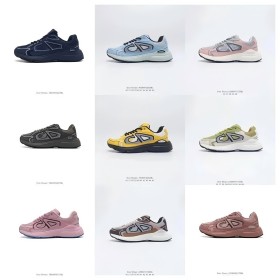

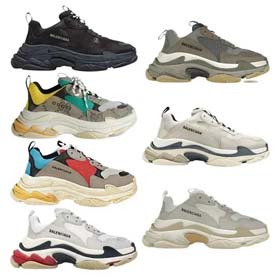

The PandaBuy platform, a leading name in the cross-border shopping industry, has revolutionized the way quality control (QC) is conducted for imported goods. By utilizing the PandaBuy Spreadsheet, they have established a standardized QC process that brings a new level of precision and consistency to the inspection of products.This innovative approach involves quantifying various quality indicators such as the density of stitching in garments and the texture of leather goods. These metrics are meticulously recorded and entered into the PandaBuy Spreadsheet, which serves as a central repository for all quality-related data.The QC team at PandaBuy employs the spreadsheet's image comparison feature to generate comprehensive reports. These reports not only include detailed descriptions but also visual aids, allowing for a clear understanding of the product's condition from multiple angles. Defects, if any, are highlighted and annotated within the images, providing a transparent view of the product's quality to both the platform and its users.Users can access these detailed reports directly within the PandaBuy Spreadsheet, where they can view high-quality, real-life images of the products, complete with defect annotations. This feature empowers customers to make informed decisions and ensures that they receive products that meet their expectations.Furthermore, PandaBuy dynamically adjusts supplier ratings based on the QC data collected. This data-driven approach allows the platform to identify and maintain relationships with suppliers who consistently deliver high-quality products. It also helps in weeding out those who fail to meet the platform's stringent quality standards, thus safeguarding the overall quality and reliability of the cross-border shopping experience.In conclusion, PandaBuy's adoption of the PandaBuy Spreadsheet for QC purposes has not only streamlined their operations but also significantly enhanced the quality assurance process. It sets a new benchmark for the industry, ensuring that customers receive the best possible products from overseas, every time.